Welcome to Saturn Spraying Systems

Saturn Spraying is a leading supplier of spraying technology for the food production industry globally and has supplied clients worldwide for the past 30 years with our food production equipment.

Specialists in Food Spraying Technology

Saturn Spraying is a leading provider of innovative food technology solutions. With expertise in automated spraying, we offer precise and controlled sprays to enhance food preservation, flavour, and quality.

Our spraying techniques optimise coverage and reduce waste, benefiting a wide range of food products, from fruits and vegetables to dairy and bakery items. Saturn Spraying specialises in food preservation, extending shelf life with natural coatings and preservatives.

We excel in flavour enhancement, delivering precise and enticing flavours and aromas to various food and beverage applications. Additionally, our spraying techniques enhance the appearance of food products, creating visually appealing coatings, glazes, and finishes.

Wherever you are located in the world, we can deliver you a spraying machine that integrates with your food production line.

Talk To Us

Talk To UsWhy Choose SATURN SPRAYING SYSTEMS?

Choosing Saturn Spraying Systems offers numerous advantages, including cutting-edge technology, extensive expertise, versatile applications, natural and sustainable solutions, comprehensive support, and a customer-centric approach. A food spraying machine with spinning disc technology provides several benefits, which include:

Efficient and uniform coating

The spinning disc technology ensures that the food coating is applied uniformly and consistently.

Reduced wastage

The controlled and targeted spray mist generated by the spinning disc technology minimizes wastage.

Time-saving

The spraying machine with spinning disc technology can coat food items at a faster rate compared to traditional methods, saving valuable time.

Versatility

These machines can handle a wide range of food products, including baked goods, confectioneries, snacks, and even fresh produce, offering versatility in application.

Hygiene and cleanliness

The spray mist produced by the spinning disc technology reduces the need for manual handling of coating materials, promoting a cleaner and more hygienic environment.

Improved quality control

The uniform coating achieved by the spinning disc technology helps maintain consistent quality across food products, ensuring improved quality control.

Products Completely Customised For You

At Saturn Spraying, we specialise in offering a wide range of high-quality food spraying machines designed to meet the diverse requirements of various industries and applications.

Each machine is completely bespoke. It is custom designed and built to suit the specific needs of each one of our customers.

Industries that we serve

At the core of Saturn Spraying's expertise lies their mastery of atomised spraying technology. They have developed advanced systems capable of delivering precise and controlled sprays to food products, ensuring optimal coverage and minimal waste. Whether it's fruits, vegetables, dairy products, or bakery items, their spraying techniques are tailored to enhance the taste, appearance, and shelf life of a wide range of food products.

One of Saturn Spraying's primary focuses is food preservation. They understand the challenges faced by manufacturers and distributors in preserving perishable items. With their specialised spraying solutions, they can apply natural preservatives or coatings that help extend the shelf life of food products without compromising their quality or taste. This breakthrough technology not only reduces food waste but also enables companies to deliver fresher products to consumers.

Fruits & Vegetables Application Area

Learn more about how Saturn's products can enhance your industry by increasing production and automating processes.

Read more

Meat, Fish & Cheese Application

Learn more about how Saturn's products can enhance your industry by increasing production and automating processes.

Read more

Biscuit & Snacks

Learn more about how Saturn's products can enhance your industry by increasing production and automating processes.

Read more

Bakery Products

Learn more about how Saturn's products can enhance your industry by increasing production and automating processes.

Read more

Want To Talk To Someone?

Do you have an application that could use this technology?

Loved by business and individuals across the globe

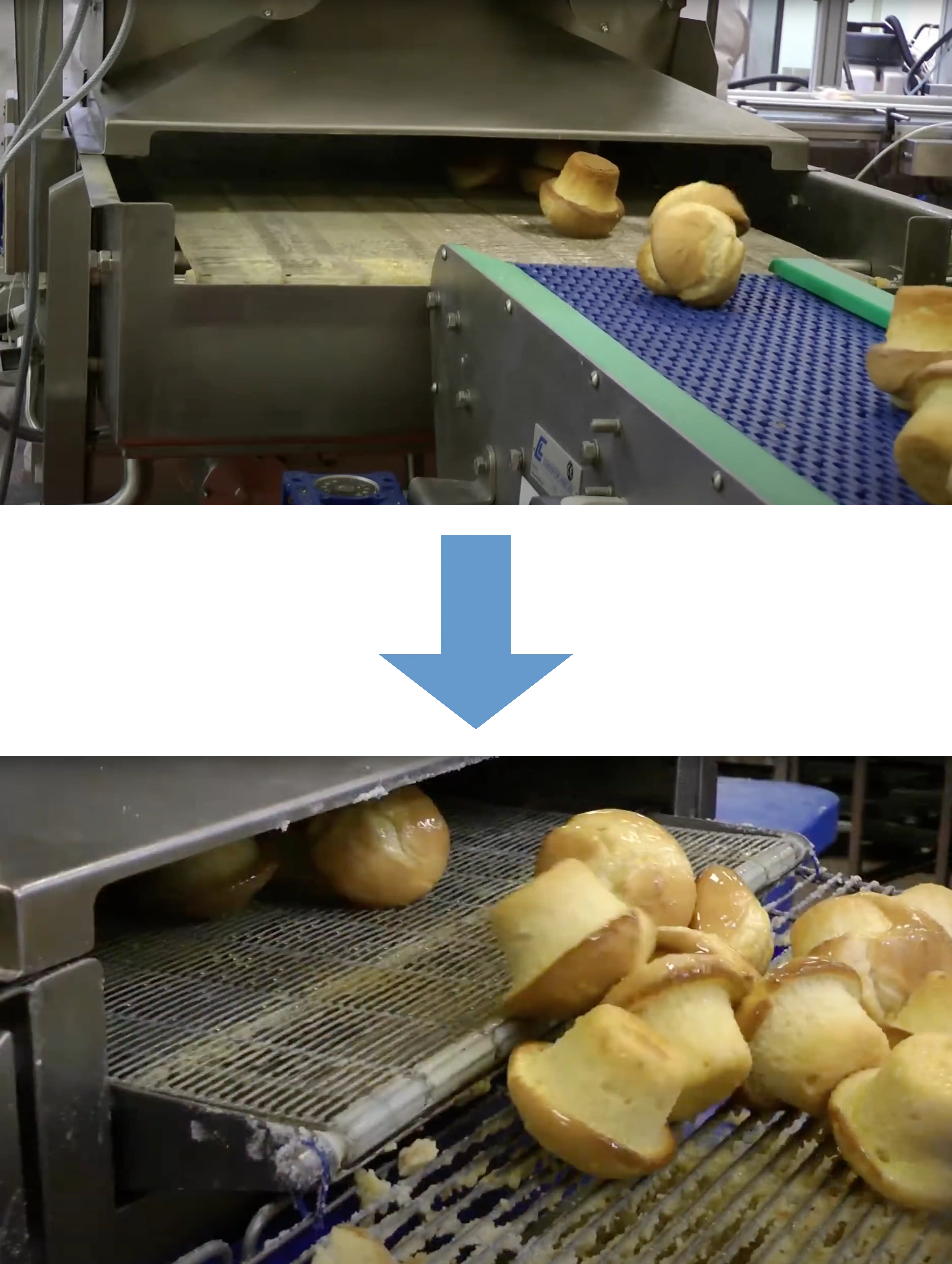

"Our machine was delivered at 1300 hrs. today ( Wednesday).

We unpacked it and immediately put it into production.

The finished glaze on our Hi-Glaze buns is just about perfect. It is obvious, even at this early stage that we will achieve a very big saving on the amount of glaze we use. We now have a very clean and easy to use system, and will save on both production and cleaning costs. "

Brendan Coghlan

Managing Director | Coghlan’s Bakery

"Crantock purchased their first Spraying System from Saturn in 2002, adding further Saturn systems as our production expanded. Our last purchase was manufactured, delivered, installed and operational in only seven weeks from the order.

Since moving into this role, I have been very impressed not only with the quality of Saturn’s spray glazing, but also how reliable the equipment has proven to be. Our planned maintenance program, has with Saturn’s Spares support, more than achieved the high uptime rates demanded by our production."

Alan McGillivray

Engineering Manager | Crantock Bakeries Limited

" ….. some of our products require a controlled level of emulsion, which we need to monitor very closely. We ensure that it’s even and within a close tolerance by weight, by batch. For us the repeatability and precision of the Saturn Spraying Machine have been a major factor in providing a reduced fat, coated fish product into the market."

Peter Tiffney

Technical Director | Five Star Fish Ltd, 2 Sisters Food Group

Satisfied Customers

249

Countries served

25

Stations installed

68

We work with multiple agents across the globe

These agents are in your local country and help us ship our products to you

Got Questions?

We may not be suitable for everyone. Here are some answers to common questions to help you decide if our service is right for you.

Can I split the costs and make payment in instalments?

Certainly! We can help you arrange a payment plan through our approved finance company. However, please note that we do have our standard payment terms in place.

Will the machinery meet my specific needs? Can you provide examples of fields where it is commonly used?

Absolutely! To better understand your requirements, we will send you a client information request form. Once we have gathered all the necessary details, we will be able to make tailored recommendations based on your specific needs. Our machinery has been successfully employed in various fields, such as the bakery sector, fruits and vegetables, meat and fish, and low-fat products.

Will I receive assistance with the assembly process?

No, our machine is delivered fully assembled and ready to use. However, we do offer additional services, such as training and a commissioning package, which can be arranged at an extra cost.

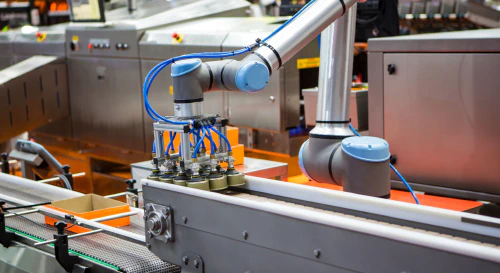

Will this product help me increase my production?

Absolutely! Our machine is designed to enhance production efficiency. By replacing manual operations, it enables faster and more cost-effective results. Many of our clients have experienced significant improvements in their production processes.

Can I customise the products to suit my specific requirements?

Yes, in some cases. The possibility of customisation will depend on the specific changes you need. Once you discuss your customisation needs with our engineering department, we can evaluate the feasibility of implementing the required modifications.

What type of warranty do you offer for your products?

We provide a standard 1-year warranty for all our machinery. Additionally, since we manufacture our own replacements for the machine, we can also recommend a basic spares package to accompany your purchase.

Didn’t find the answer? Contact us here

Latest news from our blog

2024-10-10

How Modern Food Spraying Automation Is Boosting Shelf Life in 2024

Discover how modern food spraying automation is revolutionizing the food industry in 2024 by extending shelf life, reducing waste, and preserving food quality.

Read more

2024-08-07

What is Food Spraying? A closer look into Saturn's food spraying technology

Food spraying machines offered by Saturn Spraying bring a pyramids of benefits to food production factories. From enhancing productivity and yield to ensuring precision and repeatability in glazing, oiling, and emulsifying, our machines revolutionize manufacturing processes.

Read more